For more than 15 years “ATC Chains India” has been known for ethical and responsible business practice. We value this reputation and we are dedicated to furthering the principles set out by our founder “MR. AJAY PATEL”.

Our Story

Mr. Ajay believed that companies are built on doing the right thing each and every day, and treating customers, employees and vendors honestly, fairly and with respect. These principles are reflected in ATC’s business philosophy. We aim to practice this every single day, for benefits of our customers.

Moreover, ATC is 100% committed to give the quality and services that has been promised to the customers. Each time we work with you, Fulfilling the requirements of our clients will be our topmost priority each.

Why Us

Reasons why ATC Chains India is known for best service in this segment:

• 1 year guarantee on all ATC products. We also give accidental guarantee which is provided by no other company all over world.

• Fastest delivery all over globe.

• A healthy product range of 1100+ products to choose from.

• Only manufacturer of modular belts in India, due to which any customization is easily possible and one will get best rate in market.

• 24*7 Technical support available.

• Technically educated staff to provide you best service

WE WORK HARD, WE PLAY HARD

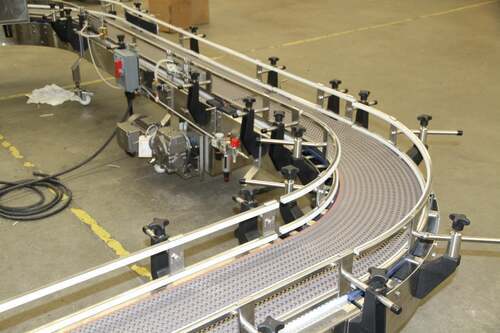

WORK WITH USBottling Industry

Bottling industry has wide range of applications such as fillers (pet/glass/can/jar/spout), warming/colling tunnels, labeller, bottle/case washer, palletizer/depalletizer, all type of conveyors.

ATC provides all type of slat chains, sprockets, wear-strips and all type of components for the bottling industry. All products under one roof only

Vegetable And Fruits processing

The fruit and vegetables industry requires plastic modular belts resistant to wear, heat and humidity - and easy to clean. ATC has been supplying this kind of belts since years and is successful in that application.

Along others, the applications count: Blanchers/coolers, pasteurizers, cooling conveyors, washer tanks, fruit packing, washing of vegetables, cutting.

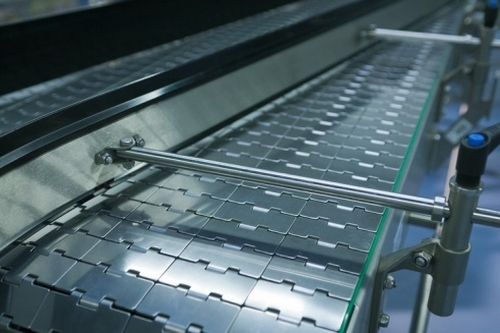

Packaging Industry

When packaging OEMs choose to work with ATC, they increase their productivity, reduce costs and improve worker safety with conveyance solutions that bring all the benefits of modular plastic belting to complex material handling processes like bundle and pallet handling, 90 degree turning, and WIP storage areas.

We provide our customers with industry-specific expertise, and premium products and equipment that give you the competitive advantage of efficiency, speed and savings.

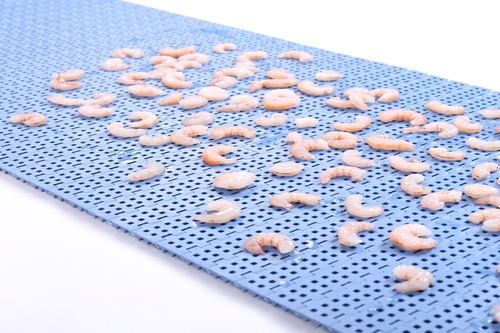

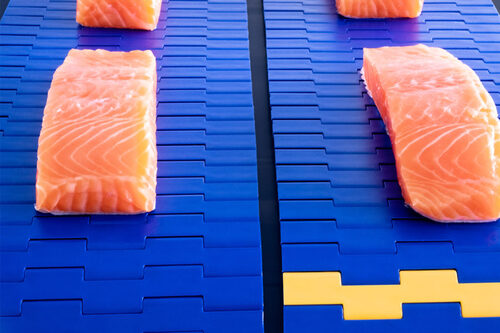

Meat, Poultry And Fishery

Hygiene is extremely important when operating in the meat and seafood industry. Cleanability is a keyword along with impact resistance, tensile strength, belt surfaces (non-stick, airflow, drainage, etc.) and fast and simple maintenance. ATC’s Modular belts supply all this with our unique products – and we can even add optimization of throughput in high volume operations with space limitations.

Some of the common applications are : Offal conveyors, cutting lines, deboning lines, box handling, packing lines, shrink wrap, metal detectors, elevator conveyors.

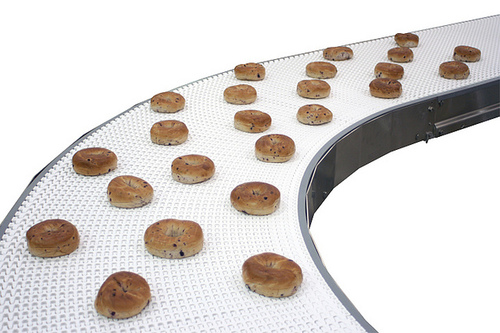

Snacks Processing Industries

We’ve worked with snack producers around the world to help them increase profitability by reducing maintenance costs and unscheduled downtime and increasing product throughput.

ATC’s solutions have long been applied in traditional applications such as peeler-to-sorter, incline-to-packaging, and various applications in the back end of snack plants. we are helping our customers be more profitable in areas such as potato receiving, processing, and packaging.

Paint Industry

ATc’s various range of products such as flat top chains and belts, wearstrips, sprockets, components etc. are widely used in paint filling and processing machines.

We provide complete range of conveyor assembly for paint filling machines.

E-commerce And Logistics

ATC’s modular provides reliable solutions for the logistics industry. Supplying not only belts featuring high load capacity but also belt solutions designed to merge and combine, turn products, re-position products and in or decrease product spacing – and last but not least belts that increase the safety of the plant worker.

The advantages are : Lower maintenance costs, longer service life – economical transport solution, multidirectional conveyance, high load capacity, increased worker safety.